Silo Dust Collectors: An Essential Solution for Industrial Dust Control

Silo Dust Collectors

Silo Dust Collectors

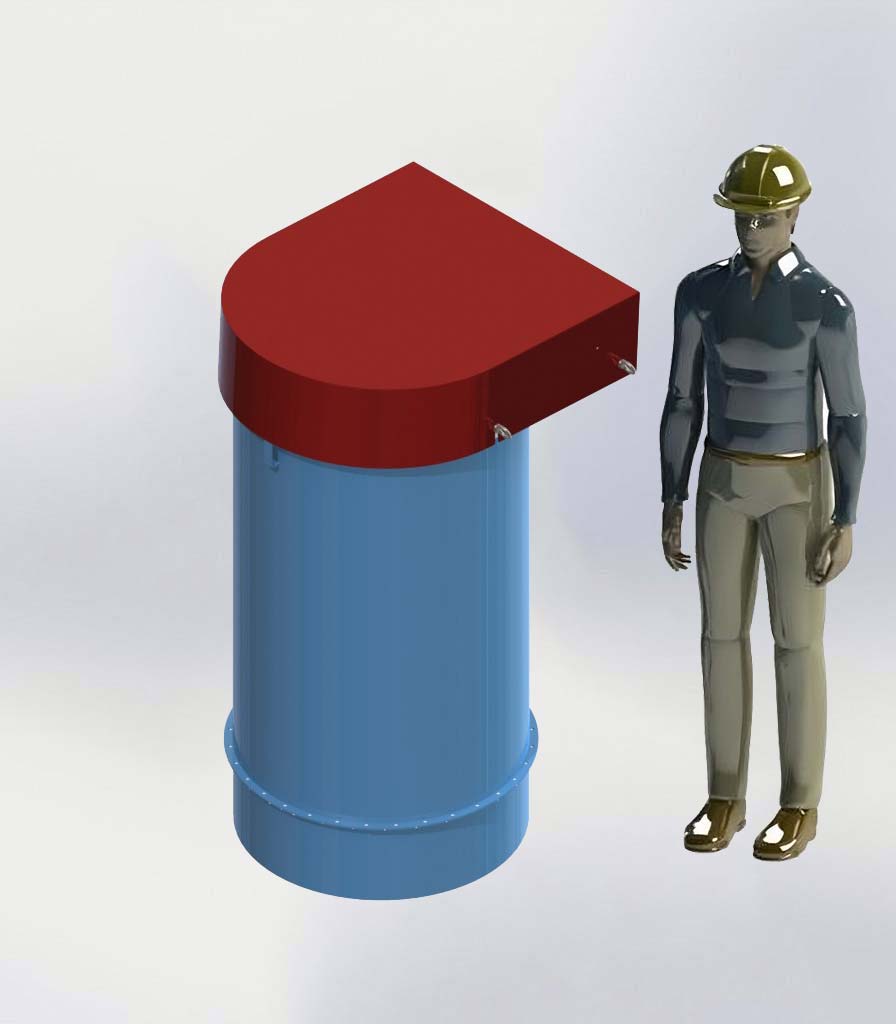

Silo dust collectors play a vital role in managing dust emissions in industrial facilities. These specialized systems are designed to capture and filter out airborne particles, preventing them from being released into the surrounding environment. By employing silo dust collectors, industries can significantly reduce the concentration of dust in the air, creating a safer and healthier work environment.

How Silo Dust Collectors Work

Silo dust collectors utilize a combination of filtration and airflow principles to capture and contain dust particles. The system is typically installed near the dust generation source, such as silos, hoppers, or material transfer points. As dusty air enters the collector, it passes through a series of filters that trap the particles while allowing clean air to pass through.

Stages of Silo Filter Calculation

- Customer Survey: Determining the type of production and the nature of the dust generated.

- Preparation of a Technical Specification: Compiling a technical document based on the gathered data.

- Preparation of a Technical and Commercial Proposal: Creating a proposal that includes both technical and commercial aspects.

- Development of a Dimensional Drawing: Creating a detailed drawing that illustrates the dimensions and specifications of the silo filter.

It is crucial to ensure accurate calculations and drawings to ensure the proper functioning of the installation. Incorrect calculations or drawings may result in improper or non-functional operation. We recommend seeking the assistance of professionals in this field for all calculations and manufacturing processes.

For a free calculation, please contact Torch-Air company!

Key Components of Silo Dust Collectors

Silo dust collectors consist of four key components: the filtration system, dust discharge mechanism, cleaning mechanism, and control system.

The filtration system uses various filter media such as woven fabric, non-woven fabric, cartridges, and bags to effectively capture dust particles of different sizes. The choice of filter media depends on the specific application and particle size.

To remove the collected dust from the system, dust discharge mechanisms like rotary valves or screw conveyors are utilized. These mechanisms ensure controlled removal of accumulated dust, preventing clogging and maintaining the collector’s efficiency.

Cleaning mechanisms, such as pulse-jet or reverse air systems, are employed to prevent clogging and maintain filter effectiveness. These mechanisms create a pressure differential to dislodge dust from the filters, ensuring continuous operation and optimal dust collection efficiency.

The control system is integral to silo dust collectors, providing automation and monitoring capabilities. It allows for adjustments in airflow, cleaning cycles, and sends alerts for maintenance and filter replacement. Advanced control systems can integrate with plant-wide control systems for seamless operation and data analysis.

Comments are closed.